Martensitic steel

KLEINOX 4543–455 KL – CUSTOM 455 – DIN EN X3CrNiCuTiNb12-9 – AISI XM-16 – ASTM F899

USES AND APPLICATIONS

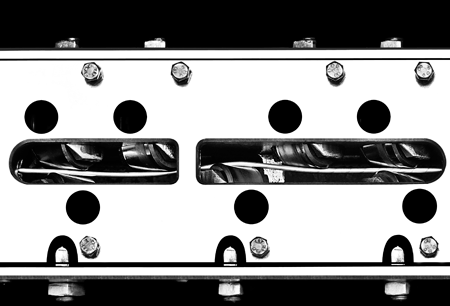

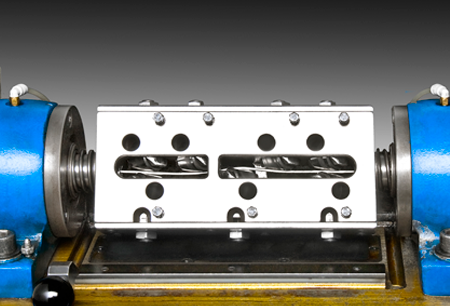

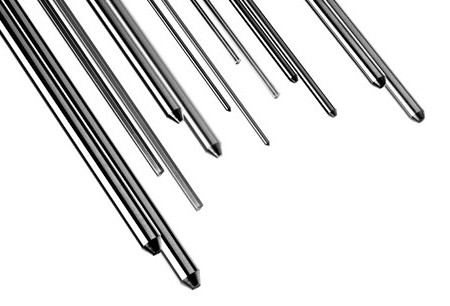

KLEINOX 4543 (AISI XM-16) is a precipitation hardenable martensitic stainless steel. Its main attribute is its simplicity to use. Its forming is easy and the parts made out of it present a good corrosion resistance, similar to this of 15-17%Cr martensitic stainless steels. Furthermore, its stress corrosion resistance increases with the age hardening intensity. In the age hardened condition it has a high strength coupled with an excellent toughness. Performing a correct heat treatment, it may reach 48 HRc hardness. This steel is well indicated for the production of surgical instruments, cutting tools, surgical needles and spindles.

EXECUTIONS

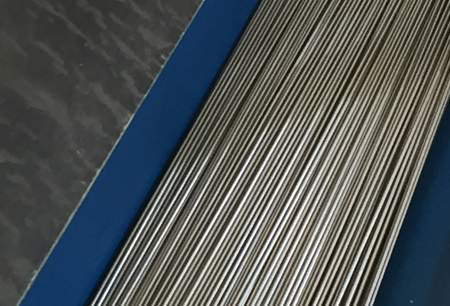

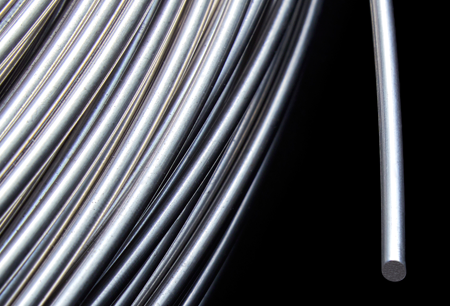

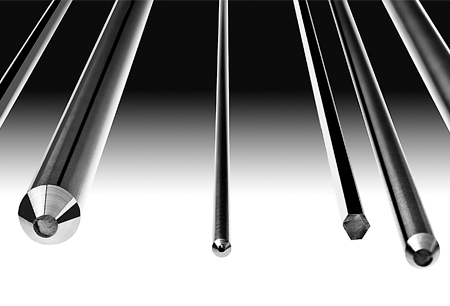

Diameters: 1.00 – 15.00 mm

Tolerances: ISO h8 (up to h5)

Delivery conditions: in cold drawn or ground bars 3m and Coils

MECHANICAL PROPERTIES

Magnetism: magnetized

Welding: good welding, no preheating avoid ozyacetylene welding

Cold working: it’s recommended utilization at anneal condition (A condition)

Cutting speed: 25-35 m/min

Heat treatment: solubilization: 480 – 540°C; furnace or air cooling

Precipitation hardening: 480 – 540°C. 4h furnace. air cooling.

Resiliency E 20°C: (GPa) 200

Specific weight: (kg/dm³) 7,76

Heat conductivity 20°C: (W/m K) 18,0

Specific Heat 20°C: (kJ/kg K) 0.46

Electrical resistivity: (Ω mm²/m) 0.76

Prodotti correlati

KLEINOX 4571

KLEINOX 4571 acciaio austenitico altamente resistente ad ossidazione e acidi. Per la produzione di componenti per le industrie chimica, alimentare e tessile

KLEINOX 2516

KLEINOX 2516 lega di cromo-vanadio-tungsteno. Adatto a diversi usi, in particolare utensili da taglio, trapani a spirale, piercing, mandrini, frese, punzoni, estrattori, alesatori, etc